What Product Types Do Metal Film Resistors Include?

I. Introduction

A. Definition of Metal Film Resistors

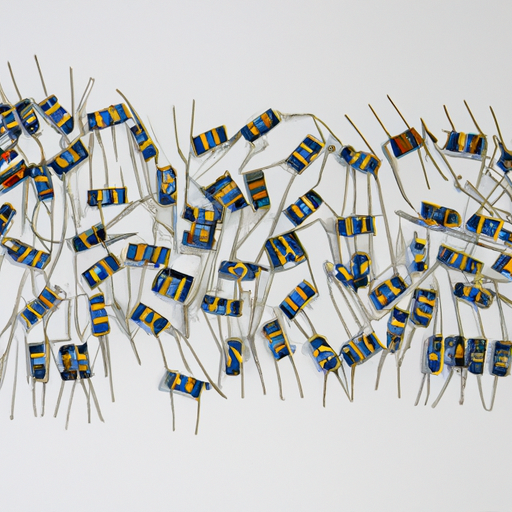

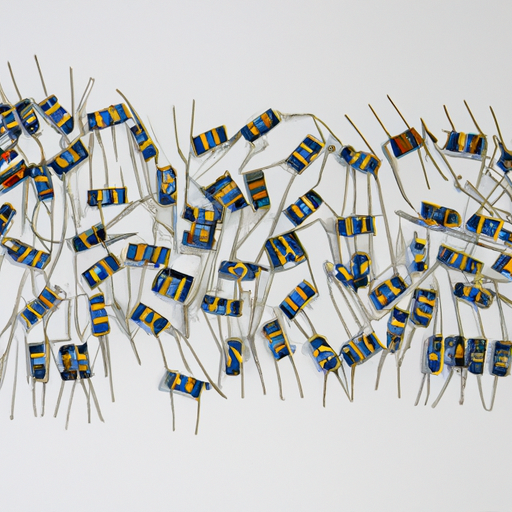

Metal film resistors are passive electronic components that provide resistance in electrical circuits. They are made by depositing a thin layer of metal onto a ceramic substrate, which is then etched to create a precise resistance value. This construction allows for a high degree of accuracy and stability, making metal film resistors a popular choice in various electronic applications.

B. Importance of Metal Film Resistors in Electronics

In the world of electronics, resistors play a crucial role in controlling current flow, dividing voltages, and protecting sensitive components. Metal film resistors, in particular, are favored for their low noise, high precision, and excellent temperature stability. These characteristics make them essential in applications ranging from consumer electronics to industrial machinery.

C. Overview of the Article

This article will explore the different product types of metal film resistors, their characteristics, applications, and how they compare to other resistor types. By the end, readers will have a comprehensive understanding of the significance of metal film resistors in modern electronics.

II. Understanding Metal Film Resistors

A. Composition and Structure

1. Materials Used

Metal film resistors are primarily composed of a thin layer of metal, typically nickel-chromium or tantalum, deposited on a ceramic substrate. The choice of materials contributes to the resistor's performance characteristics, including its resistance value, temperature coefficient, and stability.

2. Manufacturing Process

The manufacturing process involves several steps, including the deposition of the metal film, etching to create the desired resistance value, and the application of protective coatings. This precision manufacturing allows for tight tolerances and consistent performance across batches.

B. Characteristics of Metal Film Resistors

1. Tolerance and Precision

One of the standout features of metal film resistors is their high precision. They typically have tolerances as low as 0.1%, making them ideal for applications where accuracy is paramount.

2. Temperature Coefficient

Metal film resistors exhibit a low temperature coefficient, meaning their resistance value changes very little with temperature fluctuations. This stability is crucial in environments where temperature variations can affect circuit performance.

3. Stability and Reliability

These resistors are known for their long-term stability and reliability, making them suitable for critical applications where failure is not an option.

III. Types of Metal Film Resistors

A. Standard Metal Film Resistors

1. Description and Applications

Standard metal film resistors are the most common type, used in a wide range of applications. They offer good performance at a reasonable cost, making them suitable for general-purpose use in consumer electronics, industrial equipment, and more.

2. Common Specifications

Typically, standard metal film resistors have tolerances of 1% to 5% and power ratings ranging from 1/8 watt to several watts, depending on the size and application.

B. Precision Metal Film Resistors

1. Definition and Features

Precision metal film resistors are designed for applications requiring the highest levels of accuracy. They often have tolerances as low as 0.01% and are constructed to minimize drift over time.

2. Applications in High-Precision Circuits

These resistors are commonly used in instrumentation, medical devices, and aerospace applications, where even the slightest deviation can lead to significant errors.

C. Low-Noise Metal Film Resistors

1. Characteristics and Benefits

Low-noise metal film resistors are engineered to minimize electrical noise, making them ideal for sensitive applications such as audio equipment and RF circuits.

2. Use Cases in Audio and RF Applications

In audio applications, low-noise resistors help maintain signal integrity, while in RF applications, they reduce interference, ensuring clearer transmission.

D. High-Power Metal Film Resistors

1. Overview and Design Considerations

High-power metal film resistors are designed to handle larger amounts of power without overheating. They typically feature larger physical sizes and enhanced thermal management.

2. Applications in Power Electronics

These resistors are commonly used in power supplies, motor control circuits, and other applications where high power dissipation is required.

E. Surface Mount Metal Film Resistors

1. Description and Advantages

Surface mount metal film resistors are designed for modern electronics, allowing for compact designs and automated assembly processes. They are typically smaller than traditional through-hole resistors.

2. Applications in Modern Electronics

These resistors are widely used in smartphones, tablets, and other compact devices where space is at a premium.

F. Specialty Metal Film Resistors

1. Overview of Custom and Niche Products

Specialty metal film resistors include custom designs tailored for specific applications, such as high-voltage or high-frequency environments.

2. Applications in Specific Industries

These resistors find use in niche markets, including telecommunications, automotive, and military applications, where standard resistors may not meet the required specifications.

IV. Comparison with Other Resistor Types

A. Metal Oxide Resistors

Metal oxide resistors are known for their high power ratings and stability but typically have higher noise levels and lower precision compared to metal film resistors.

B. Carbon Film Resistors

Carbon film resistors are less expensive but offer lower precision and stability than metal film resistors, making them suitable for less critical applications.

C. Wirewound Resistors

Wirewound resistors provide high power ratings and precision but can be bulkier and less suitable for high-frequency applications due to inductance.

D. Advantages and Disadvantages of Metal Film Resistors

Metal film resistors offer high precision, low noise, and excellent stability, but they can be more expensive than other types, which may limit their use in cost-sensitive applications.

V. Applications of Metal Film Resistors

A. Consumer Electronics

Metal film resistors are widely used in consumer electronics, including televisions, audio equipment, and computers, where precision and reliability are essential.

B. Industrial Equipment

In industrial settings, these resistors are used in control systems, automation equipment, and instrumentation, ensuring accurate performance under varying conditions.

C. Medical Devices

The medical industry relies on metal film resistors for devices such as diagnostic equipment and monitoring systems, where accuracy can be a matter of life and death.

D. Telecommunications

In telecommunications, metal film resistors are used in signal processing and transmission equipment, where low noise and high reliability are critical.

E. Automotive Applications

Modern vehicles utilize metal film resistors in various electronic control units, ensuring precise operation of systems such as engine management and safety features.

VI. Future Trends in Metal Film Resistor Technology

A. Innovations in Manufacturing

Advancements in manufacturing techniques, such as improved deposition methods and materials, are expected to enhance the performance and reduce the costs of metal film resistors.

B. Emerging Applications

As technology evolves, new applications for metal film resistors are emerging, particularly in fields like renewable energy and electric vehicles, where precision and reliability are paramount.

C. Environmental Considerations

With increasing focus on sustainability, manufacturers are exploring eco-friendly materials and processes to reduce the environmental impact of metal film resistor production.

VII. Conclusion

A. Summary of Key Points

Metal film resistors are versatile components that play a vital role in modern electronics. Their various types, including standard, precision, low-noise, high-power, surface mount, and specialty resistors, cater to a wide range of applications.

B. The Role of Metal Film Resistors in Modern Electronics

As technology continues to advance, the demand for high-precision, reliable components like metal film resistors will only grow, solidifying their place in the electronics industry.

C. Final Thoughts on Product Types and Applications

Understanding the different product types of metal film resistors and their applications is essential for engineers and designers looking to optimize their electronic designs. With their unique characteristics and advantages, metal film resistors will remain a cornerstone of electronic circuit design for years to come.

VIII. References

A. Academic Journals

- IEEE Transactions on Electron Devices

- Journal of Electronic Materials

B. Industry Publications

- Electronic Design Magazine

- EDN Network

C. Manufacturer Specifications and Data Sheets

- Vishay Intertechnology

- Yageo Corporation

This comprehensive overview of metal film resistors highlights their importance, versatility, and the various product types available, providing valuable insights for anyone involved in electronics design and manufacturing.

What Product Types Do Metal Film Resistors Include?

I. Introduction

A. Definition of Metal Film Resistors

Metal film resistors are passive electronic components that provide resistance in electrical circuits. They are made by depositing a thin layer of metal onto a ceramic substrate, which is then etched to create a precise resistance value. This construction allows for a high degree of accuracy and stability, making metal film resistors a popular choice in various electronic applications.

B. Importance of Metal Film Resistors in Electronics

In the world of electronics, resistors play a crucial role in controlling current flow, dividing voltages, and protecting sensitive components. Metal film resistors, in particular, are favored for their low noise, high precision, and excellent temperature stability. These characteristics make them essential in applications ranging from consumer electronics to industrial machinery.

C. Overview of the Article

This article will explore the different product types of metal film resistors, their characteristics, applications, and how they compare to other resistor types. By the end, readers will have a comprehensive understanding of the significance of metal film resistors in modern electronics.

II. Understanding Metal Film Resistors

A. Composition and Structure

1. Materials Used

Metal film resistors are primarily composed of a thin layer of metal, typically nickel-chromium or tantalum, deposited on a ceramic substrate. The choice of materials contributes to the resistor's performance characteristics, including its resistance value, temperature coefficient, and stability.

2. Manufacturing Process

The manufacturing process involves several steps, including the deposition of the metal film, etching to create the desired resistance value, and the application of protective coatings. This precision manufacturing allows for tight tolerances and consistent performance across batches.

B. Characteristics of Metal Film Resistors

1. Tolerance and Precision

One of the standout features of metal film resistors is their high precision. They typically have tolerances as low as 0.1%, making them ideal for applications where accuracy is paramount.

2. Temperature Coefficient

Metal film resistors exhibit a low temperature coefficient, meaning their resistance value changes very little with temperature fluctuations. This stability is crucial in environments where temperature variations can affect circuit performance.

3. Stability and Reliability

These resistors are known for their long-term stability and reliability, making them suitable for critical applications where failure is not an option.

III. Types of Metal Film Resistors

A. Standard Metal Film Resistors

1. Description and Applications

Standard metal film resistors are the most common type, used in a wide range of applications. They offer good performance at a reasonable cost, making them suitable for general-purpose use in consumer electronics, industrial equipment, and more.

2. Common Specifications

Typically, standard metal film resistors have tolerances of 1% to 5% and power ratings ranging from 1/8 watt to several watts, depending on the size and application.

B. Precision Metal Film Resistors

1. Definition and Features

Precision metal film resistors are designed for applications requiring the highest levels of accuracy. They often have tolerances as low as 0.01% and are constructed to minimize drift over time.

2. Applications in High-Precision Circuits

These resistors are commonly used in instrumentation, medical devices, and aerospace applications, where even the slightest deviation can lead to significant errors.

C. Low-Noise Metal Film Resistors

1. Characteristics and Benefits

Low-noise metal film resistors are engineered to minimize electrical noise, making them ideal for sensitive applications such as audio equipment and RF circuits.

2. Use Cases in Audio and RF Applications

In audio applications, low-noise resistors help maintain signal integrity, while in RF applications, they reduce interference, ensuring clearer transmission.

D. High-Power Metal Film Resistors

1. Overview and Design Considerations

High-power metal film resistors are designed to handle larger amounts of power without overheating. They typically feature larger physical sizes and enhanced thermal management.

2. Applications in Power Electronics

These resistors are commonly used in power supplies, motor control circuits, and other applications where high power dissipation is required.

E. Surface Mount Metal Film Resistors

1. Description and Advantages

Surface mount metal film resistors are designed for modern electronics, allowing for compact designs and automated assembly processes. They are typically smaller than traditional through-hole resistors.

2. Applications in Modern Electronics

These resistors are widely used in smartphones, tablets, and other compact devices where space is at a premium.

F. Specialty Metal Film Resistors

1. Overview of Custom and Niche Products

Specialty metal film resistors include custom designs tailored for specific applications, such as high-voltage or high-frequency environments.

2. Applications in Specific Industries

These resistors find use in niche markets, including telecommunications, automotive, and military applications, where standard resistors may not meet the required specifications.

IV. Comparison with Other Resistor Types

A. Metal Oxide Resistors

Metal oxide resistors are known for their high power ratings and stability but typically have higher noise levels and lower precision compared to metal film resistors.

B. Carbon Film Resistors

Carbon film resistors are less expensive but offer lower precision and stability than metal film resistors, making them suitable for less critical applications.

C. Wirewound Resistors

Wirewound resistors provide high power ratings and precision but can be bulkier and less suitable for high-frequency applications due to inductance.

D. Advantages and Disadvantages of Metal Film Resistors

Metal film resistors offer high precision, low noise, and excellent stability, but they can be more expensive than other types, which may limit their use in cost-sensitive applications.

V. Applications of Metal Film Resistors

A. Consumer Electronics

Metal film resistors are widely used in consumer electronics, including televisions, audio equipment, and computers, where precision and reliability are essential.

B. Industrial Equipment

In industrial settings, these resistors are used in control systems, automation equipment, and instrumentation, ensuring accurate performance under varying conditions.

C. Medical Devices

The medical industry relies on metal film resistors for devices such as diagnostic equipment and monitoring systems, where accuracy can be a matter of life and death.

D. Telecommunications

In telecommunications, metal film resistors are used in signal processing and transmission equipment, where low noise and high reliability are critical.

E. Automotive Applications

Modern vehicles utilize metal film resistors in various electronic control units, ensuring precise operation of systems such as engine management and safety features.

VI. Future Trends in Metal Film Resistor Technology

A. Innovations in Manufacturing

Advancements in manufacturing techniques, such as improved deposition methods and materials, are expected to enhance the performance and reduce the costs of metal film resistors.

B. Emerging Applications

As technology evolves, new applications for metal film resistors are emerging, particularly in fields like renewable energy and electric vehicles, where precision and reliability are paramount.

C. Environmental Considerations

With increasing focus on sustainability, manufacturers are exploring eco-friendly materials and processes to reduce the environmental impact of metal film resistor production.

VII. Conclusion

A. Summary of Key Points

Metal film resistors are versatile components that play a vital role in modern electronics. Their various types, including standard, precision, low-noise, high-power, surface mount, and specialty resistors, cater to a wide range of applications.

B. The Role of Metal Film Resistors in Modern Electronics

As technology continues to advance, the demand for high-precision, reliable components like metal film resistors will only grow, solidifying their place in the electronics industry.

C. Final Thoughts on Product Types and Applications

Understanding the different product types of metal film resistors and their applications is essential for engineers and designers looking to optimize their electronic designs. With their unique characteristics and advantages, metal film resistors will remain a cornerstone of electronic circuit design for years to come.

VIII. References

A. Academic Journals

- IEEE Transactions on Electron Devices

- Journal of Electronic Materials

B. Industry Publications

- Electronic Design Magazine

- EDN Network

C. Manufacturer Specifications and Data Sheets

- Vishay Intertechnology

- Yageo Corporation

This comprehensive overview of metal film resistors highlights their importance, versatility, and the various product types available, providing valuable insights for anyone involved in electronics design and manufacturing.